How Asbestos Exposure Occurred in Power Plants

Power plant workers maintain many types of equipment at power generation and distribution plants. These workers include pipefitters, electricians, maintenance mechanics, boiler operators and tenders, plumbers, welders, and laborers. Workers were exposed to asbestos when installing, inspecting, maintaining, repairing, removing and replacing boilers, pumps, valves, heaters, electrical boxes and other equipment.

LILCO / Long Island Lighting Co.

- Shoreham Nuclear Power Plant

- Far Rockaway Powerhouse

- Northport Powerhouse

- Barrett/Island Park Powerhouse

- Glenwood Landing Powerhouse

- Port Jefferson Powerhouse

- East Hampton Powerhouse

- Babylon Powerhouse

Niagara Mohawk

- Oswego, NY

- Nine Mile I & II

- Fitzpatrick Nuclear

- Oswego Steam Station

- Albany

- Glenmont Power Plant

- Sheridan Avenue Steam Station

- Buffalo > Huntley Station

- Dunkirk > Dunkirk Station

- Ithaca > Cornell Steam Station

- Olcott > Summerset Station

Rochester Gas & Electric

Consolidated Edison (ConEd)

- 59th Street Powerhouse-Astoria

- 74th Street Powerhouse-NY, NY

- Astoria Powerhouse-Astoria

- Ravenswood Powerhouse-Queens

- Arthur Kill Powerhouse-Staten Island

- Kent Avenue Powerhouse-Brooklyn, NY

- Hudson Avenue Powerhouse-Brooklyn, NY

- 14th Street Powerhouse- NY, NY

- 39th Street Powerhouse-NY, NY

- Indian Point Powerhouse Unit II- Buchanan, NY

- Hellgate Powerhouse-NY, NY

- East River

- Waterside

- Kips Bay

- Hunts Point

- Sherman Creek

- Van Nest

Central Hudson Gas & Electric

Orange & Rockland Utilities

- Lovett Powerhouse-Tompkins Cove, NY

- Bowline Powerhouse-Havestraw, NY

New York State Electric & Gas Company

- Dresden Power Plant-Dresden, NY

New Jersey Utilities

New York State Power Authority

- Robert Moses-Lewiston, NY

- Indian Point PH Unit III-Buchanan, NY

- St. Lawrence/Franklin Roosevelt

- Jarvis Plant

- Frederick Clark Energy

- Crescent Plant

- Vischor Ferry Plant

- Blenheim-Gilboa Plant

- Ashoran

- Kensico Project

- Poletti Project

- Fitzpatrick

What are the different types of power plants in New York?

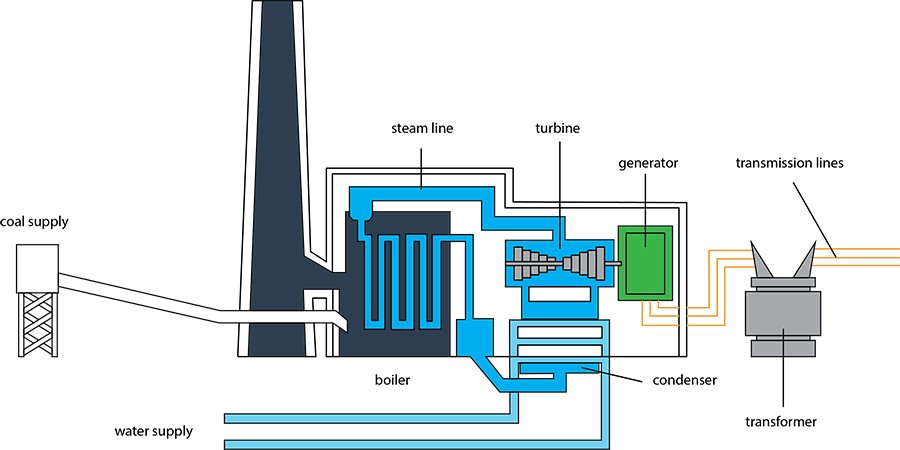

Coal Power Plant

A coal power plant burns coal in order to generate electricity. Coal power plants provide the world with one third of its electricity by turning coal into thermal energy, mechanical energy, and electrical energy. Coal power plants use fossil fuel to grind coal into tiny particles. The coal is then heated in a pulverized boiler which converts the boiler water to steam. The steam spins turbines that turn generators thus providing us with electricity.

Credit: https://en.wikipedia.org/wiki/Coal-fired_power_station

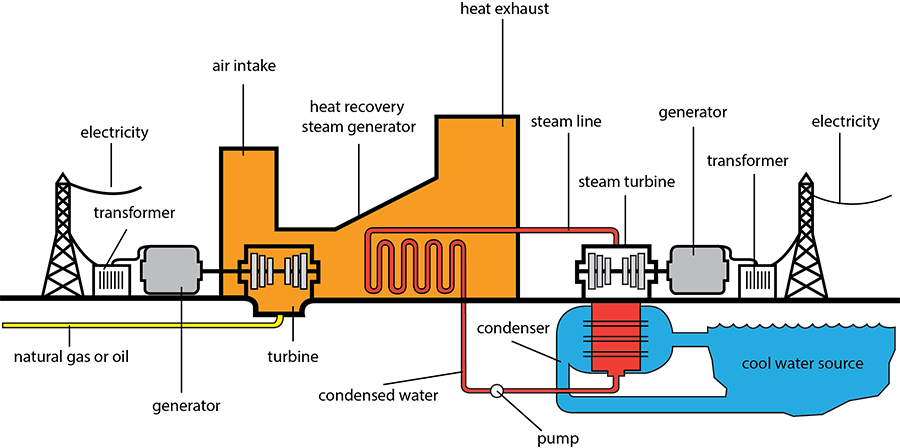

Oil/Gas Power Plant

A gas power plant is a thermal power station that burns gas to create electricity. Natural gas power stations provide the world with one quarter of its electricity. Gas power plants convert methane into thermal energy, mechanical energy, and electrical energy. There are several plant types that involve different types of turbines. One type of turbine is called a simple cycle gas-turbine which uses hot gas to drive a gas turbine to bring about electricity. The combined cycle gas-turbine uses the Brayton cycle and follows it with a heat recovery steam generator and steam turbine which use the Rankine cycle. Finally, a reciprocating internal combustion engine is used for emergency power or to balance variable renewable energy.

Credit: https://en.wikipedia.org/wiki/Gas-fired_power_plant

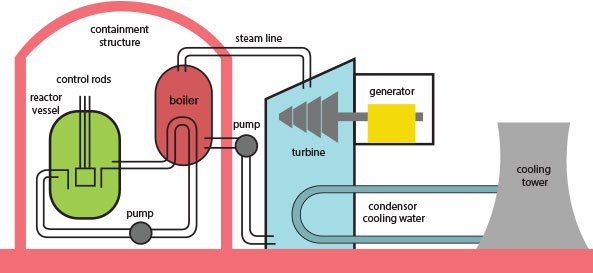

Nuclear Power Plant

A nuclear power plant is a thermal power station in which the heat source is a nuclear reactor. Heat is used to drive a steam turbine that is connected to a generator that produces electricity. There are approximately 450 nuclear power reactors in 30 countries around the world. The process of converting nuclear energy to electrical energy takes place when the fission in a nuclear reactor heats the reactor coolant. The reactor coolant then goes to a steam generator and heats water to produce steam. The pressurized steam is then fed into a steam turbine, and then the water is pumped into a steam generator. The remaining vapor is condensed in a condenser, which is attached to a cooling tower. The water is then pumped back into the steam generator and the cycle begins again.

Credit: https://en.wikipedia.org/wiki/Nuclear_power_plant

Boilers

Boilers heat water into steam which is used to create electricity. Asbestos was used to insulate the interior of the boiler and the exterior of the boiler. The interior materials were usually firebrick and refractory cement. The external insulation was usually asbestos covering in the form of cement or thermal insulation.

Boilers heat water into steam which is used to create electricity. Asbestos was used to insulate the interior of the boiler and the exterior of the boiler. The interior materials were usually firebrick and refractory cement. The external insulation was usually asbestos covering in the form of cement or thermal insulation.

Boilers also used asbestos in gaskets on the boiler door, various access windows and plates, and where the boiler was connected to piping or equipment. Boilers contained many components that used asbestos packing and gaskets such as soot blowers, valves, and pumps.

Boiler workers would have to install, repair, and replace asbestos insulation on the inside and outside of boilers. This was an extremely dusty process. In addition, gaskets on boiler doors, windows, plate, and other connections would have to be changed on a regular basis. Packing in pumps and valves also had to be regularly replaced. This process was also dusty.

Turbines

Turbines take the steam from boilers and use it to turn generators to create electricity. Turbines used asbestos to insulate the inside and outside of the turbine. This asbestos was often in the form of blankets or thermal insulation. Turbines were connected to numerous pumps and valves which required asbestos-containing packing and gaskets. The packing and gaskets also contained asbestos.

Turbines take the steam from boilers and use it to turn generators to create electricity. Turbines used asbestos to insulate the inside and outside of the turbine. This asbestos was often in the form of blankets or thermal insulation. Turbines were connected to numerous pumps and valves which required asbestos-containing packing and gaskets. The packing and gaskets also contained asbestos.

When turbines were inspected and maintained, these materials had to be disturbed, exposing power plant workers to asbestos.

Pumps

Pumps and valves move water and oil to the boiler, steam to the turbines, and a variety of chemicals to other equipment. There were hundreds of pumps in powerhouses including boiler feed, steam, water, oil, chemical, and cooling pumps. These pumps were insulated with asbestos on the outside of the pump. They also contained casing gaskets and flange gaskets. Pumps also used packing in glands to seal the pump.

Pumps and valves move water and oil to the boiler, steam to the turbines, and a variety of chemicals to other equipment. There were hundreds of pumps in powerhouses including boiler feed, steam, water, oil, chemical, and cooling pumps. These pumps were insulated with asbestos on the outside of the pump. They also contained casing gaskets and flange gaskets. Pumps also used packing in glands to seal the pump.

When pumps were opened up to be cleaned, inspected, repaired or replaced, the asbestos covering on the pump was disturbed. Pump gaskets would need to be removed and replaced when pumps were repaired. Packing material would wear and need to be repaired and replaced on a regular basis.

Valves

There were thousands and thousands of valves located in power plants. Valves control the flow of material through pipes and to various pieces of equipment. Valves are insulated on the outside with asbestos. Valves also contain bonnet and flange gaskets containing asbestos and asbestos packing to seal the stem of the valve.

There were thousands and thousands of valves located in power plants. Valves control the flow of material through pipes and to various pieces of equipment. Valves are insulated on the outside with asbestos. Valves also contain bonnet and flange gaskets containing asbestos and asbestos packing to seal the stem of the valve.

When valves were repaired or replaced, the external insulation would need to be removed. Valve packing would need to replaced on a regular basis to make sure the valve stem did not leak. Gaskets on the bonnet would need to replaced when a valve was opened up for repair, and flange gaskets would need to be replaced when a valve was removed. Valve packing and gaskets would be scraped or removed, and this would create asbestos dust in the air.

Coolers, Blowers, and Fans

Coolers, blowers, and fans provide air for various processes, move material into boilers, and regulate the temperature in powerhouses. There were fans on boilers to push air through for combustion and to remove ash. Fans were insulated with asbestos and also contained asbestos gaskets and packing.

Coolers, blowers, and fans provide air for various processes, move material into boilers, and regulate the temperature in powerhouses. There were fans on boilers to push air through for combustion and to remove ash. Fans were insulated with asbestos and also contained asbestos gaskets and packing.

When workers opened up a fan for repair or inspection, asbestos insulation was disturbed and asbestos gaskets and packing would be scraped.

Other Components That Have Asbestos

Power plants have other equipment like compressors, pipes, conveyors, heaters, and evaporators that were insulated with asbestos and contained asbestos gaskets and packing.

As with other equipment, asbestos was disturbed by power plant workers during installation, repair and removal.

LEGAL HELP FOR POWER PLANT WORKERS EXPOSED TO ASBESTOS

Workers who were employed at power stations prior to the 1990s are at a high risk of developing mesothelioma, lung cancer, and other asbestos-related diseases.

Workers who were employed at power stations prior to the 1990s are at a high risk of developing mesothelioma, lung cancer, and other asbestos-related diseases.

The companies that made and sold asbestos products knew asbestos was dangerous as far back as the 1920s, yet continued selling their products for decades without warning workers or educating them about safe handling procedures.

People who have been diagnosed with mesothelioma are victims of the asbestos industry and have the right to seek compensation from the companies that caused their illness. To maximize the chance of legal success, however, it is important for asbestos victims to speak to attorneys who are thoroughly experienced in handling these types of cases.

Several industries have been involved with the Asbestos controversy – pharmaceutical plants, paper companies, metal smelting plants, food processing plants, and aerospace.

Belluck & Fox, LLP was founded to find justice for mesothelioma victims and their families. Our attorneys have a history of success in taking on the asbestos industry and have won over $1 billion on behalf of our clients. If you have been diagnosed with mesothelioma call 212-681-1575 or contact us online to set up a free consultation.

If you think you are one of the victims, seek help from our New York City trusted asbestos lawyers at Belluck & Fox, LLP now. We also have locations at NYC, Albany, Rochester, and Woodstock.

To learn more, click here to receive a free mesothelioma information package.