Schenectady Chemical

You may be entitled to receive compensation. Mesothelioma and lung cancer victims & their families have been awarded over $1 million+ from easy access to funds. Call us today to apply.

Over the past 20 years, we've helped 1,000s of families claim the compensation they deserve with no upfront costs to them.

Exposure to asbestos continues to cause thousands of cases of mesothelioma per year, primarily due to the long latency period of mesothelioma. American workers who were exposed many years ago are just now developing the illness.

Although asbestos was known to cause severe health problems by the companies that sold it, these businesses made no effort to warn the public or label their asbestos products as hazardous. An entire industry kept a decades-long silence that put millions of workers at risk. Mesothelioma victims are entitled to compensation from these companies.

People who have been diagnosed with mesothelioma need to hire attorneys who are familiar with asbestos cases. Belluck & Fox, LLP has experience with Schenectady Chemical, and can win the highest possible settlements for our clients. We have already recovered over $1 billion from businesses that sold asbestos products. Settlements obtained by our firm can pay for treatment of the disease, and can also protect your family from financial hardship. However, it is important to act quickly following a mesothelioma diagnosis because the law limits the time in which an asbestos lawsuit may be filed.

Mesothelioma Victims Deserve Justice

Table of Contents

Our law firm will make every effort to address your needs. Our experienced New York mesothelioma lawyers at Belluck & Fox, LLP can make accommodations to meet with you in your home and will handle all the work on your case, rather than referring you to another asbestos law firm. There is no financial risk on the part of our clients; we only receive payment if we recover money for you and your family. Our New York Law office can be reached at 518-621-2699 or through our online contact form.

Schenectady, New York was a hub of American industry during the twentieth century, known for its thriving manufacturing economy. Schenectady Chemical was founded by a former General Electric engineer to provide GE with specialty varnishes that they did not have the capacity to produce in bulk. Today, Schenectady Chemical – now known as Schenectady International – is a global enterprise with plants and offices in ten countries. Despite this growth, the company still maintains manufacturing plants, research labs, and its home office in the city in which it was founded.

For the better part of its existence, Schenectady Chemical used asbestos materials and equipment in its chemical plants. While asbestos was known to cause mesothelioma and other incurable diseases as early as the 1920s, the companies that produced asbestos products kept this fact secret. No warnings were printed on their products. Instead, these asbestos companies profited from the sale of a toxic substance. This has resulted in countless cases of mesothelioma, lung cancer, and asbestosis developing in workers employed at Schenectady Chemical and other industrial manufacturers. Over 3,000 Americans are still being diagnosed with mesothelioma every year.

Our firm has represented a number of clients who worked at Schenectady Chemical’s manufacturing plants in Schenectady, New York, including maintenance mechanics and kettle operators. These workers had mesothelioma from being exposed to asbestos at Schenectady Chemical. We already have records regarding Schenectady Chemical in our library, including maps, photographs, and documents that show the purchase of asbestos products from a number of companies.

Corporate History

In 1906, W. Howard Wright left his job as Chief Chemist at Thomas Edison’s General Electric Company to open his own chemical business.

The Schenectady Varnish Company was founded in response to GE’s growing need for specialty varnishes as the demand for GE products skyrocketed. With his connection to the company and intimate understanding of its needs, Wright’s new business venture was an immediate success. A production facility was erected on a six-acre plot of land along the main line of the New York Central Railroad in Schenectady. By 1925, the company had employed over 50 workers.

The Schenectady Varnish Company helped pave the way to a new era of electronics when a process was discovered to replace bulky tape insulation on wire with a thin sheath of the company’s varnish. This allowed engineers to make significant strides in reducing both the size and weight of electrical devices, turning Schenectady Varnish’s product into an industry standard.

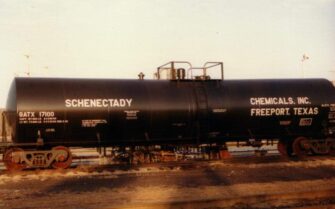

In 1962, now under the leadership of Wright’s son Henry, the company changed its name to Schenectady Chemicals, Inc. Six years later, a new research lab was completed in Niskayuna, a town just outside of Schenectady’s city limits. Over the next decades, production increased and the business expanded to a total of four sites in the Schenectady area, as well as to other locations around the country and across the globe. Focus shifted to producing chemical intermediates, which are compounds that are used in the production of other chemicals or materials. In 2006, the company changed its name to SI Group, Inc.

Asbestos Use at Schenectady Chemical

Schenectady Chemical has operated a number of separate facilities in Schenectady and the surrounding area. The original Schenectady Varnish Company production site was built in 1906 on a six-acre plot of land at the intersection of 10th Avenue and Congress Street, just north of the Rotterdam town line. The main line of the New York Central Railroad ran through the property, which served as a valuable transport resource for the company. The site was later expanded to eight acres, and three additional buildings were added. Manufacturing operations ceased at the site in 1998, and the company moved its offices to its Niskayuna site in 2000. The Congress Street site was demolished in 2008.

Schenectady Chemical has operated a number of separate facilities in Schenectady and the surrounding area. The original Schenectady Varnish Company production site was built in 1906 on a six-acre plot of land at the intersection of 10th Avenue and Congress Street, just north of the Rotterdam town line. The main line of the New York Central Railroad ran through the property, which served as a valuable transport resource for the company. The site was later expanded to eight acres, and three additional buildings were added. Manufacturing operations ceased at the site in 1998, and the company moved its offices to its Niskayuna site in 2000. The Congress Street site was demolished in 2008.

Prior to the 1990s, asbestos was widely used in much of the equipment at the Congress Street Schenectady Chemical plant contained asbestos parts. Asbestos gaskets were used throughout the plant’s fluid transport system, in pumps, valves, and other equipment. This equipment was exposed to high heat, moisture, and caustic chemicals, and would utilize these asbestos gaskets to create seals.

Asbestos gaskets would need to be scrapped off and wire brushed during regular maintenance and repair, which would create dust that was inhaled and ingested by workers. After work was complete on this equipment, new asbestos gaskets would need to be cut to size from large sheets and reapplied, often by hand and with no safety gear.

Pumps and valves would contain packing, braided rope made from asbestos, which was used to stuff the pumps and valves to create seals. This packing was often cut to length on-site, and would have to be removed from pumps with a special hook during maintenance and repair. These actions would release asbestos fibers into the air. Much of this equipment was insulated with asbestos cement and insulation. The application and removal process released asbestos particles into the air.

Around mid-century, the demand for Schenectady Chemical’s products began to outpace the production capacity at the relatively small Congress Street site. In 1951, the company established a much larger manufacturing complex in Rotterdam Junction, located about eight miles northwest of the original production site. This new chemical factory was built on a 60-acre plot of land along the Mohawk River and, as of 2013, remains active at its original 1000 Main Street address.

Asbestos was used in this new site in much the same way as at the company’s Congress Street site. In addition to pumps and valves, caustic chemicals were often stored in vessels and tanks lined with asbestos. Motorized machines would often use asbestos as a lining for brake pads, which would wear and release asbestos dust as a result of its intended use. It could also be found lining furnaces and reaction vessels used to catalyze chemical reactions and create new chemicals.

Asbestos affects not only workers who worked on this equipment, but everyone nearby. This is because when asbestos fibers are released into the air, they contribute to an overall contamination of the environment in the plant. Since asbestos has a tendency to settle on clothes, shoes, hair, and skin, even the families of these workers were not safe. Workers would bring home asbestos on their person, unknowingly exposing their families to the dust. Many people have been diagnosed with mesothelioma due to this “take-home” asbestos exposure.

In 1968, now officially under the name Schenectady Chemicals, the company completed construction of a large research and office facility on Balltown Road in Niskayuna. The complex was built on nearly ten acres of property located roughly six miles northeast of the original Congress Street site. Named the W. Howard Wright Research Library in honor of the company’s founder, the site became the home office of Schenectady International in 2000, when the company permanently closed its Congress Street site. No production was to occur here; only research and business.

A fourth production site was added in the early 90s. Located on Broadway in Schenectady, this 95,000 square foot facility was less than a mile north of the Congress Street site. The site itself was constructed in 1915 for its previous owners, Mica Insulators.

Associated Occupations

Other Nearby Companies

- General Electric Plants

- ALCO

- Albany Felt Company